Is there a coolant low warning on your instrument cluster? Do you need to top up your vehicle’s coolant weekly or fortnightly? Pink crystallised stains on your garage floor?

If you drive a vehicle from the Volkswagen group with a 1.8 TFSI or a 2.0 TFSI petrol engine, manufactured between 2008 and 2022, you may need a standard coolant pump module replacement.

If you have any of these symptoms, it is recommended to have your vehicle inspected by a professional without delay to mitigate the risk of more expensive engine failures or breakdowns.

More about these engines

These engines are known as the EA888, which you can also find in AUDI cars, and they come in 3 different generations. To identify these engines, all of them are petrol turbocharged, chain-driven, have variable valve timing on either the exhaust camshaft or both camshafts, and have plastic coolant modules that house the coolant pump and thermostat in one module.

(You can call us and we can identify your particular engine for your coolant pump module replacement, or if you’re a bit more technical, you can do a quick search and find some information on Google.)

Finding the leak

To determine if the issue is with the coolant pump, it is recommended to take the vehicle to a trained professional. He will, if needed, perform a coolant pressure test. This is a tool that will pressurise the cooling system and force coolant out from any area where there is a leak.

If this leak is in the area under the intake manifold, it is almost a certainty that it comes from this plastic module. Pink coolant crystals can also identify these leaks on the left (longitudinal fitment) or on the front (transverse fitment) of the engine and oil pan. (See figures 1 & 2)

The module can leak from either the coolant pump, the thermostat or the body of the module.

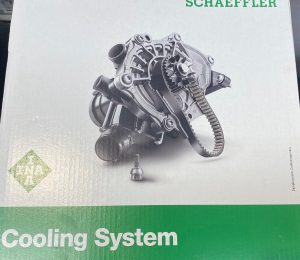

Use the latest parts for this repair.

These coolant modules have been updated several times with improvements, and different companies manufacture them. If your coolant pump is indeed leaking, ensure that your mechanic uses the latest version of this part from either an authorised dealer or an aftermarket supplier that supplies original equipment parts.(Figure 4.) The part numbers vary by engine generation; your mechanic will use your VIN to source the correct part for your vehicle.

The parts that will be replaced are a new coolant pump module, a coolant union and a new drivebelt. (See figures 5 & 6)

In the workshop

Your mechanic will drain the old coolant from your engine into a container for recycling.

He will then continue to disconnect connectors and move electrical harnesses out of the way. Remove the throttle body and disconnect any coolant hoses from the coolant module. He will now unscrew the coolant module and remove it with the coolant union.

Next up is to replace the little drivebelt and then fit the new coolant module with a new union. Figures 6 & 7)

Now all the removed and disconnected parts are refitted in reverse order.

After the coolant pump module replacement, your mechanic will vent the cooling system of any air. Evaluate the system to see if there are any leaks, and then fill the cooling system with a mixture of coolant and water. Let the engine run until it reaches operating temperature and recheck the coolant level afterwards.

Concluding thoughts

It is important always to have the correct coolant/water ratio in your engine, and if you have any leaks, to have it looked at as soon as possible.

I hope that this short article will give you more information if you have this type of failure on your vehicle, and how vital the correct repair and parts are to prevent any rework.

If you have any further questions or need any advice, please do not hesitate to contact us on 09 394 4533 or at www.vorsprungautomobil.co.nz.